I set myself the target for today of getting the transmission ready to lift and to remove the bulkhead. No pressure but I really did want to get to this milestone. Perhaps not the end of the beginning and all that but still a milestone. Or millstone?

First off was the front prop shaft. Easy albeit oily and the access wasn’t great even with most of 05 KD 28 removed. Then came the gearbox tie rod – a dinky little thing to help stop the engine going through the radiator – which had seen better days.

Back at the business end I started on the pedal boxes. First was the clutch mainly as I had had this out before to replace the master cylinder and it was straight forward. Next the brake pedal for which I thought I would remove the servo first.

The actual pedal box was a little stiffer to get out than the clutch but came out soon enough to reveal the accuracy of the previous paint jobs and an extra hole.

Steering column was next up and I removed the shroud to find I had left the keys in the ignition. Steering wheel off, and the electrics released I removed the bulkhead support.

I should say at this point that I have not referred to a manual or anything similar to work out how to take 05 KD 28 apart. I am working to a ‘look and undo’ model.

The steering column is actually more involved than I thought it would be, but logic worked. Step one: undo biggest nut you find.

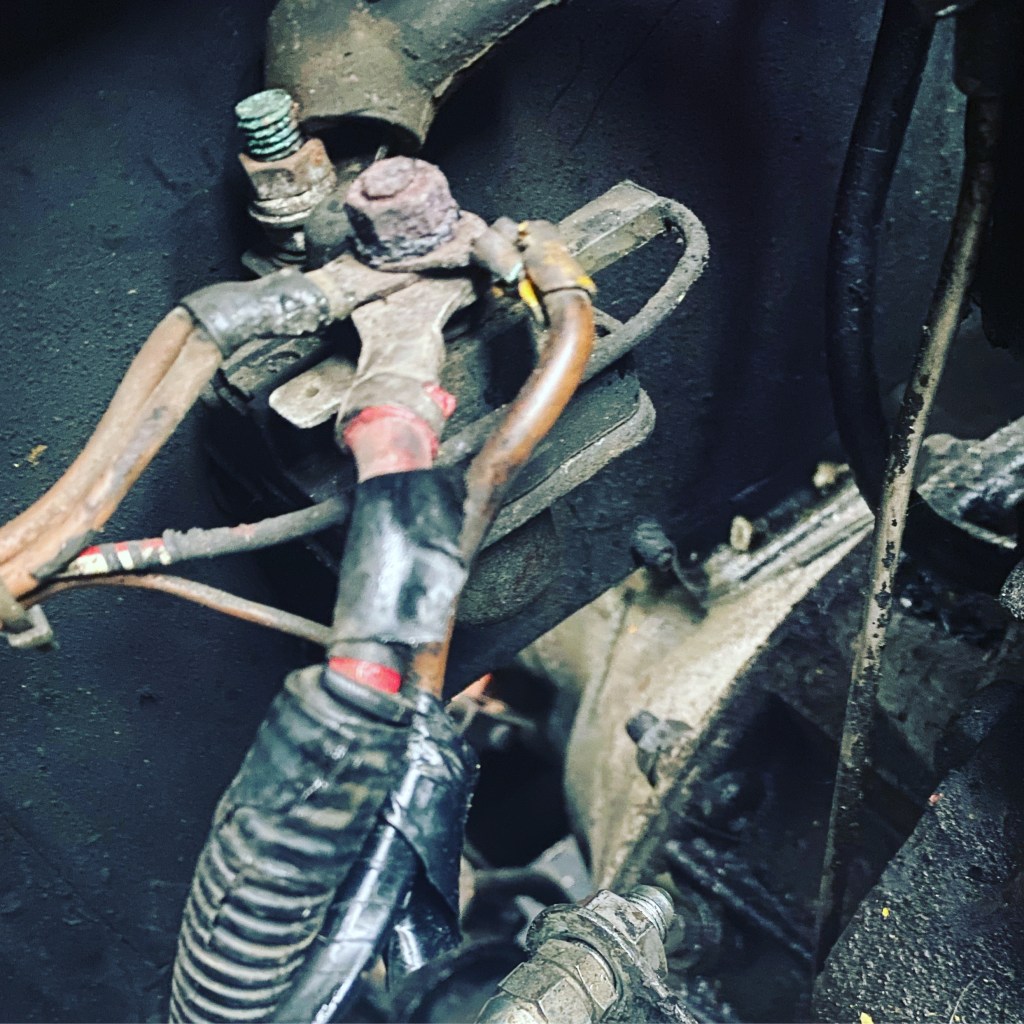

Next was the attempt to get the arm off the steering box shaft. Ball joint extractor? No. Bearing puller? Yes but ….

My bearing puller was about two Rizla papers and a 3/16 tho too long to fit. So off came the distributor. I am sure I should have marked something but ….

It has been a miserable day today and blowing a hooley, so with impeccable timing I was called to deal with a tree that had blown over into the road. Took a little time as chainsaw wouldn’t start but cut it up and then towed the last bit out of the ditch and onto drive to cut up. No Health and Safety breaches at all, honest.

I still have a milestone to reach today!!