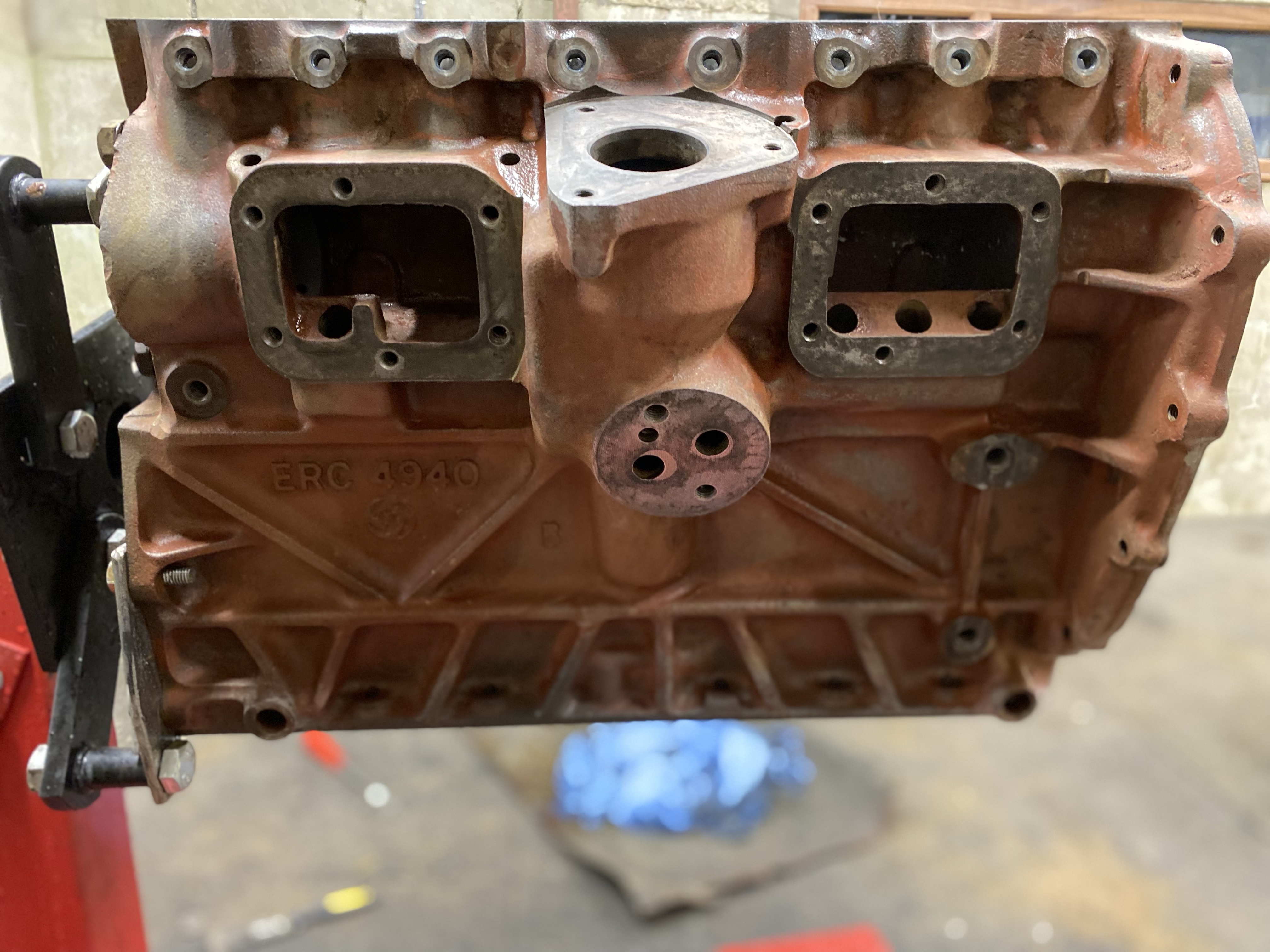

A little bit of tidying of the workshop was required before moving onto cleaning the block, and starting to clean the head (I’ll start stripping that later once I have tidied a bench) and the pistons.

Armed with my scrapers and gasket removal spray, I attacked the gaskets, scrape, spray, leave, spray, scrape etc etc. The Loctite is actually pretty good but best to remove as much as possible first. It also softens carbon deposits – more on that later.

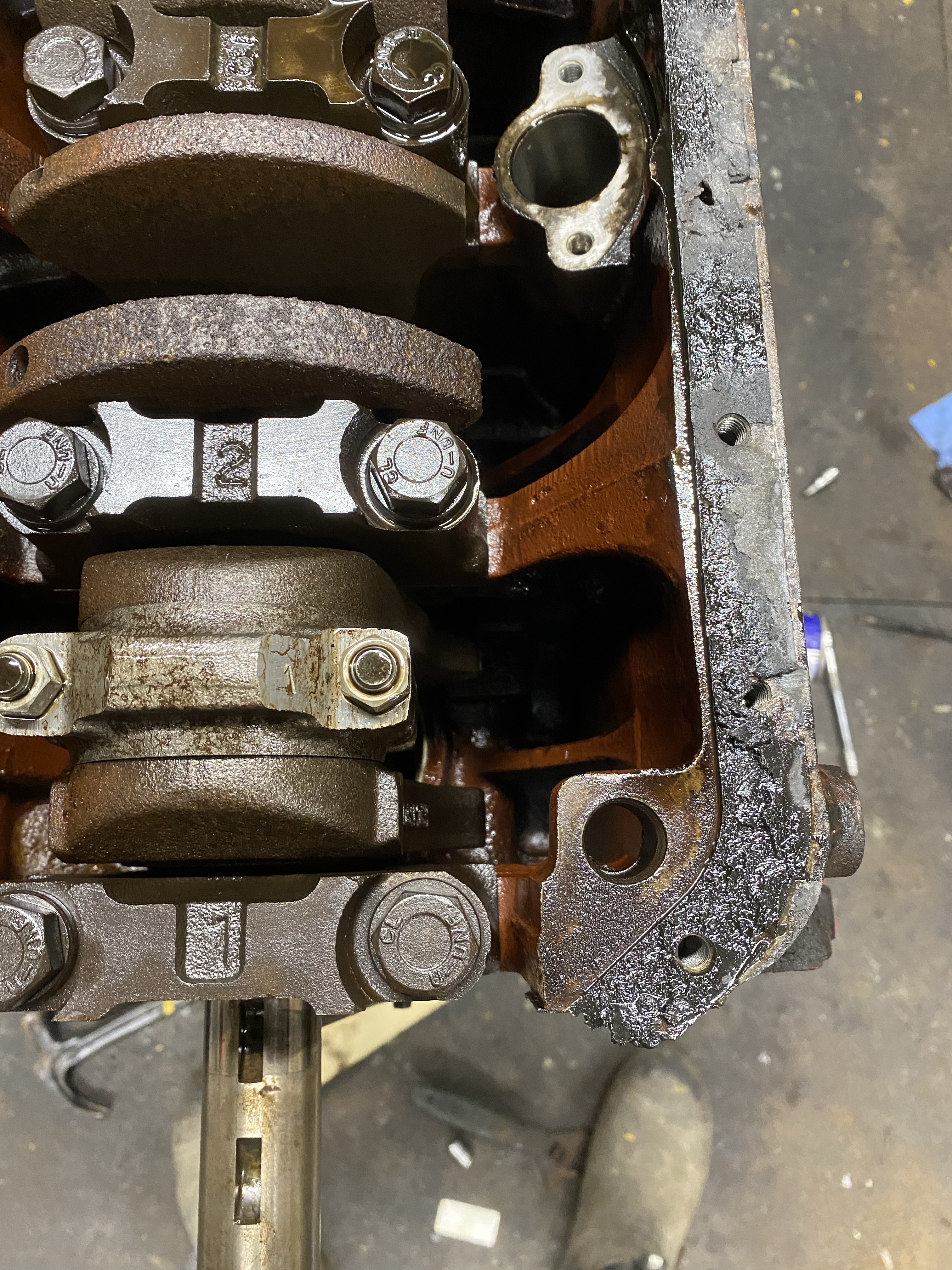

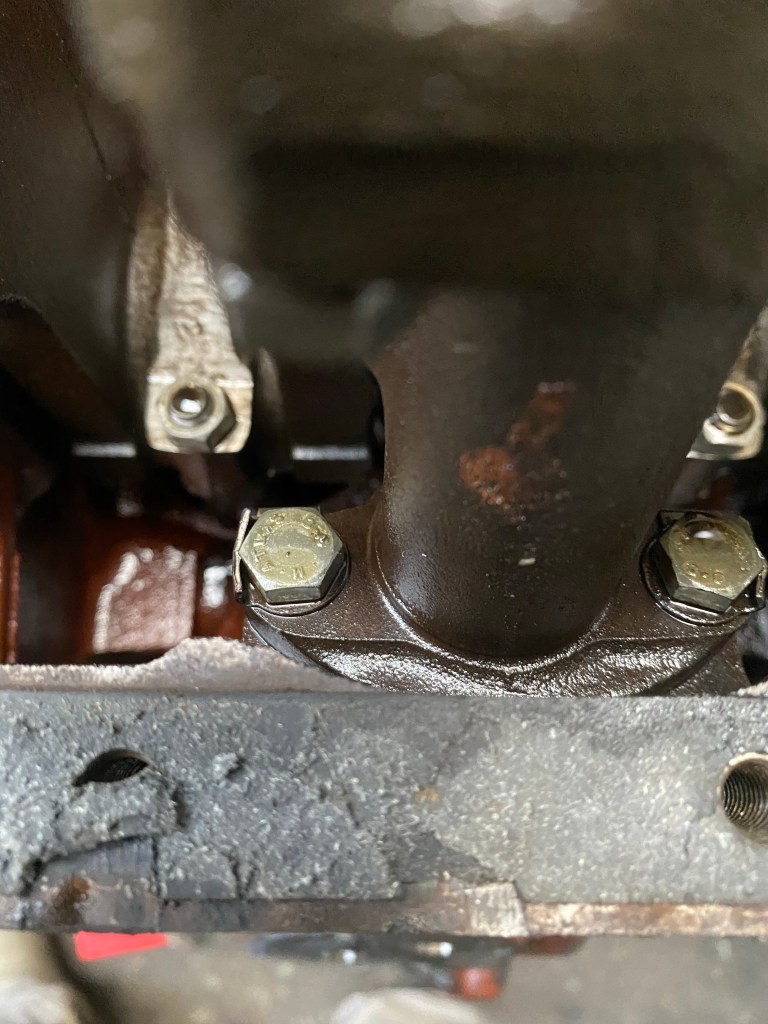

Gaskets removed I set to the outside and inside of the block with engine degreaser and a brush. This cleared most of the collected oil, but a jet wash removed the rest. It’ll need prep cleaner before painting but it is pretty clean. I also took the chance to blast through the coolant galleries. It may be better to have done this with core plugs removed, but I am still in two minds about replacing them. If it ain’t broke don’t fix it said the man who had to pull the engine again.

I dried the block with compressed wire and wiped the cylinder bores and sealing faces with light oil.

Over to the head and pistons. I thought whilst I was cleaning the block I would go lean the faces of the head and remove the carbon from the valves and pistons.

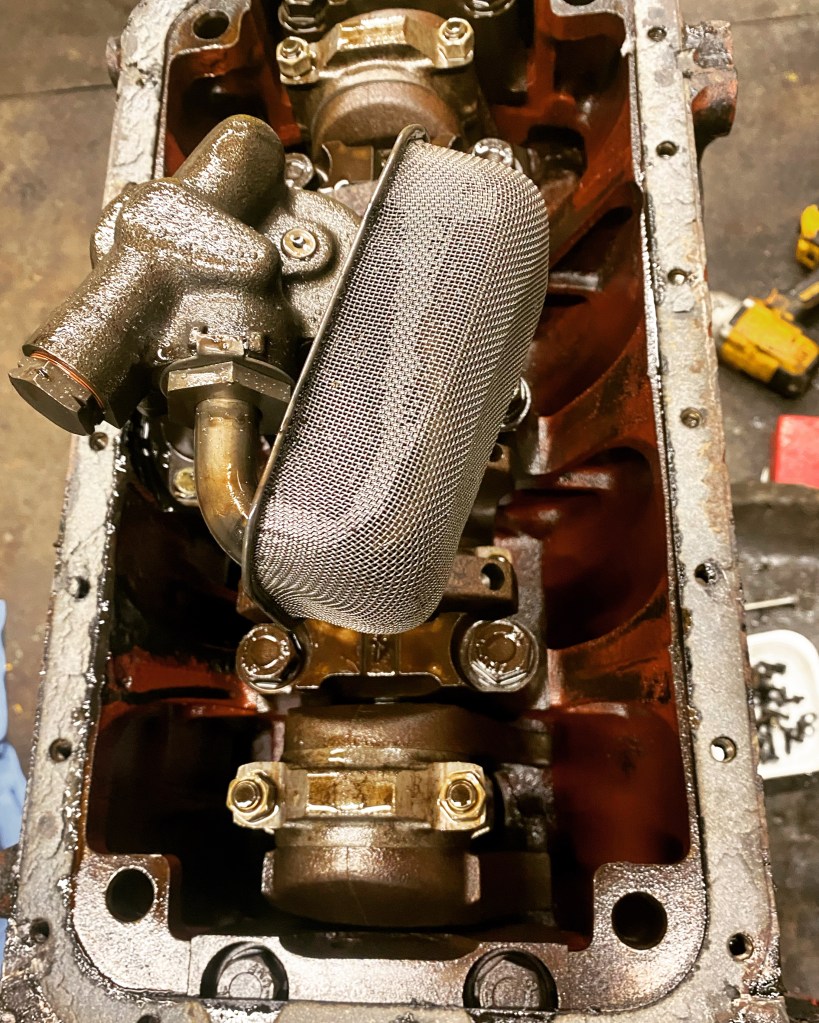

Head looks ok (no obvious cracks between 2 and 3) and given the thick layer of carbon came off the valves I started thinking this may equate to more horses and would it be worth also porting the head. At this point I started cleaning the pistons. Scraping, spraying, scraping and spraying and scrubbing and they were coming up well until ….

A cracked crown is not a good thing. A broken crown whilst the engine is running is a very bad thing. One has to find silver linings. Now the question is replace just this one or all four? The core plugs are looking cheap now!