The head had waited patiently for its turn to be stripped and cleaned. Today was the day. A little bit of a look around suggested that all might not be well.

Four easy bolts took the rocker assembly off. Fortunately this needs only a good clean, but it’s removal allowed me to glimpse the issues that lay ahead. Next job was to remove the collets and release the valves. All straight forward until No.5 (Cylinder 3 exhaust) which seemed a bit loose.

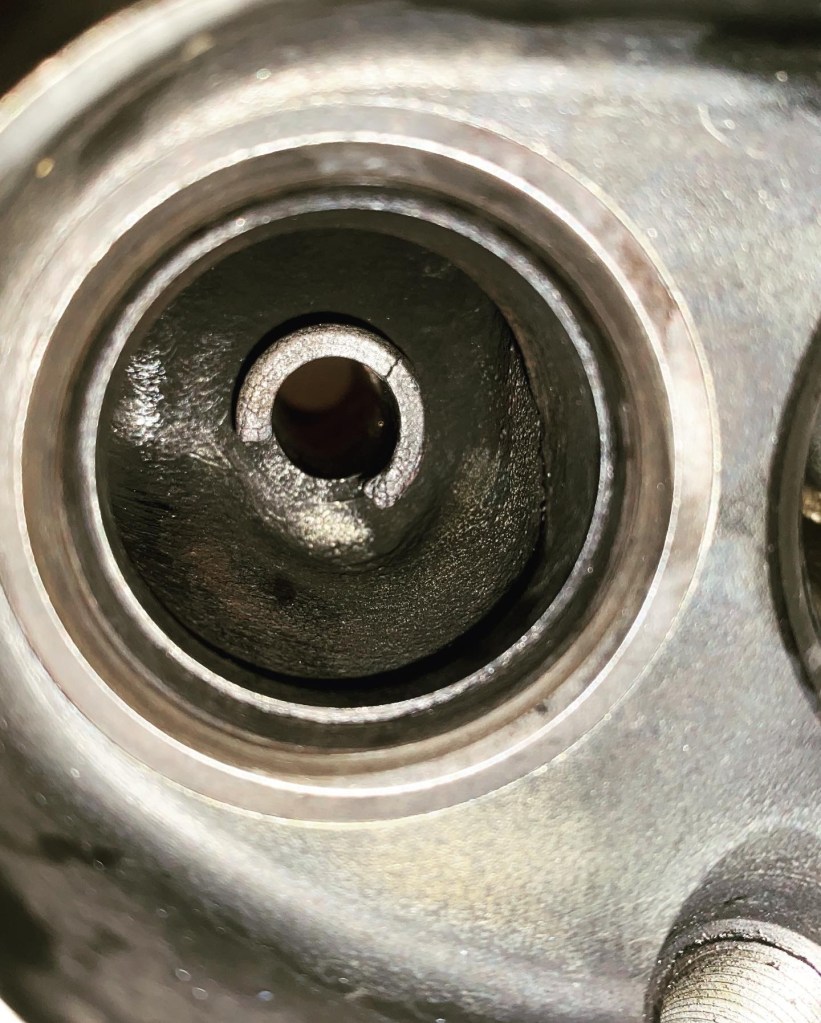

All springs and valves out, the state of the stem seals could be assessed. All hardened and ineffective, but No. 5 was missing quite a bit. The stem of this valve told the story.

Clearly I had been burning a bit of oil. I was not, however, expecting the valve to be so loose in the guide, although some of the slop had been taken up with burnt oil. Closer inspection revealed that the copper liner was absent and the guide had fractured.

Well this means a new set of guides is needed. I believe the saying is ‘in for a pound, in for a lot of pounds’. At this juncture, whilst debating a machine shop or a combination of my oven and freezer, I decided to carry on with cleaning the head. They is some very minor pitting between cylinders 2 & 3, but it is flat in this area. If a skim is needed then that answers the guide question.

Next up is painting the block and deciding how best to replace the front crank seal, but maybe finishing painting the chassis now the loom has arrived. Oh wait, maybe the springs and axles or ………..