A rather more productive day than yesterday. I decided that the old chassis had to complete its journey and so out came the angle grinder and into smaller pieces went the chassis. If I was in any doubt about the need to replace chassis, I was no more after this.

Chassis chopped the 130 was brought into service as a hearse, taking an ancestor to the promised land (well a tip).

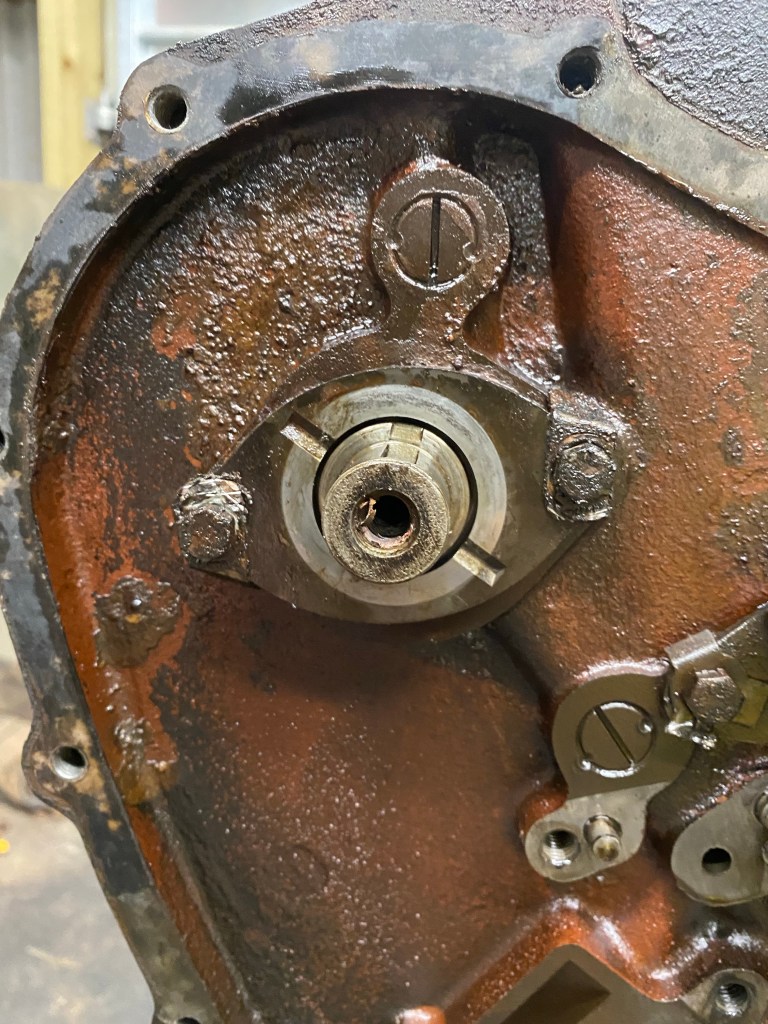

Back to the engine rebuild I set myself the target of getting to a bare block today. First job was to remove the starting dog.

The pulley came off easily with a bearing puller, using the starting dog as a base to pull against and to stop the pulley flying off. I did however notice that the pulley has some damage, it looks like a slight dent that has cracked the casting. Maybe a No. 1 persuader was used instead of a No. 2?

.

With the pulley off the timing case could be unbolted and pulled free.

A bit of fiddling got the chain tensioner out – there is probably an official way but mine also worked. The crank and cam sprockets came away easily along with respective keys. Next out we’re the cam followers, the securing bolts are Loctite secure rather than being drilled and wired.

With the cam shaft retaining plate removed I thought the shaft would slide out. No, bearings won’t clear the oil pump / distributor gear. How is it held in? I turned to the parts book for inspiration.

Now to find where this grub screw was burrowed. Think like Land Rover!

Buried under the gasket for the oil filter assembly was the screw, it turned easily and and the pump gear slid out easily. The cam shaft also now slipped out nicely.

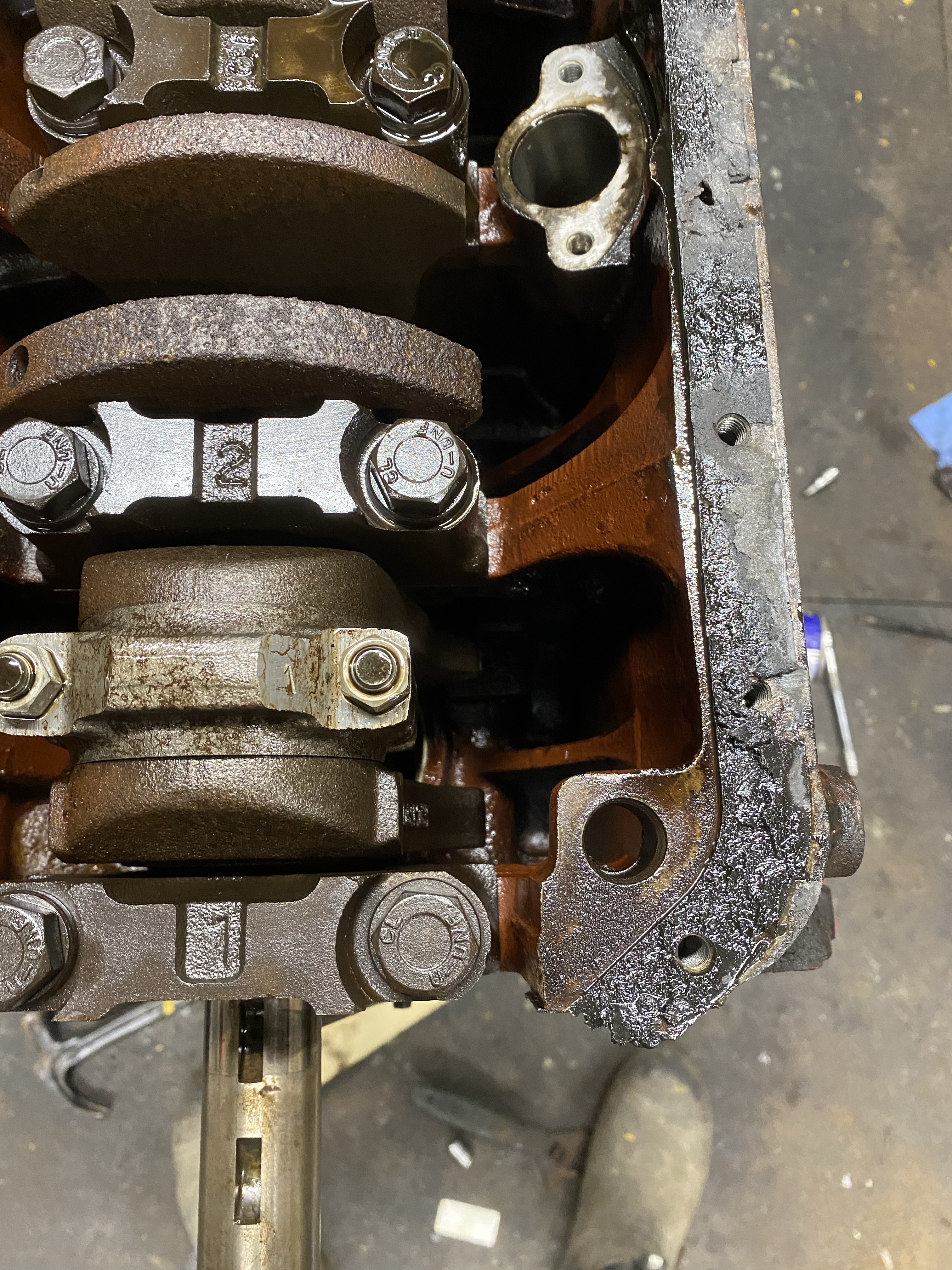

Time to spin the block over and removed the 5 MB and disconnect the pistons.

The pistons actually came out easily – there was barely a wear ridge – but they do need a bit of TLC. Block now naked save for the cam shaft bearings and core plugs (none of which are leaking) it was time to finish.